Home PCB Assembly Service

PCBNPI ELECTRONICS® is more than just a PCB manufacturer. We also provide a high-quality consigned, turnkey or mixed assembly service. So we are the one-stop destination for board fabrication and assembly company. This arrangement makes your R&D work easy and time-saving.

● Files Requirements

○ PCB file: Gerber RS-274X format;ODB;common EDA's like .pcb,.brd;

○ BOM: To ensure an efficient assembly process, you need to provide a clean BOM and assembly notes with all the necessary callouts such as reference designators, part numbers quantities, package, assembly side ect.

○ Pick & place file: List reference designators ,x /y coordinates, rotation angles, placement side ect. If you couldn't provide, some extra expense will be charged.

○ All polarity part's assembly direction should be marked clearly on silkscreen layer to avoid error appearing.

If not, please provide some other file to assist us to resolve any ambiguities about component polarity and physical placement, such as schematic diagram and assembly drawing.

For more information, please download and check our example files of BOM sheet, pick & place file and assembly drawing.

● Assembly Capabilities

○ SMT, Through hole, Cable assembly and mixed assembly.

○ Single or double sided placement.

○ Passive down to 0201 Sizes.

○ Ball Grid Array (BGA).

○ Quad Flat Pack No-Lead (QFN).

○ Quad Flat Package (QFP).

○ Plastic Leaded Chip Carrier (PLCC) 6. SOIC, Package-On-Package (PoP).

○ Fine pitch FPC connector (Pitch of 0.2 mm).

● Service Types

○ Prototype assembly, no MOQ limited.

○ Production assembly,high speed automated machines can handle production orders.

○ Cable assembly and box build.

○ Consigned assembly (kitted), partially consigned and turnkey assembly

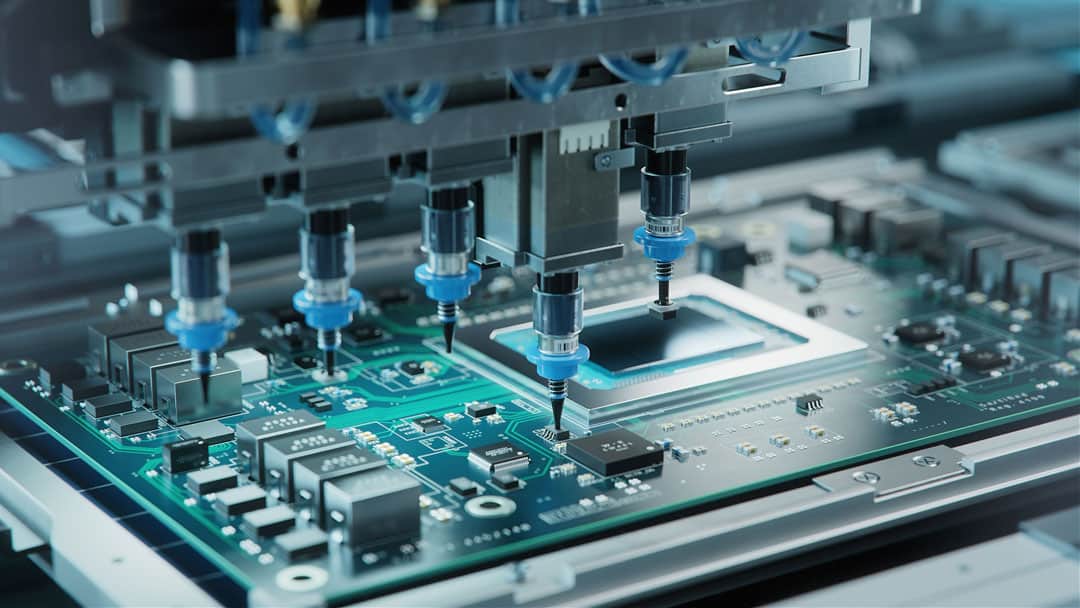

● Assembly Process

○ Engineers confirm/review the necessary files and order details;

○ Manufacture SMT stencil (laser cut stainless steel stencil);

○ Program pick & place file from the BOM sheet and centroid file;

○ Verify all incoming materials (PCBs,components, fixtures/tools & stencils) and handling quality problems before subsequent SMT assembly begins;

○ Bake components and PCBs (if necessary);

○ Machine assembly:

1.Solder paste printing➜ 2.SPI checking➜ 3.Component placement➜ 4.Visual inspection/technical confirmation➜ 5.Reflow soldering➜ 6.Automated optical inspection (AOI)

○ Through hole parts sordering;

○ Board washing, hand assembly checking & final quality inspection;

○ programing & functional testing (if necessary);

○ Packaging & shipping.

At PCBNPI ELECTRONICS@, a specially-assigned engineer follows up all above procedures and your sales will contact you when we any questions found.

● Quality Assurance

○ Files checking (DFM & DFA) before PCB production/assembly;

○ Components order from authorized distributors like Digikey,Mouser;

○ At least 2 engineers (Production Engineer, Process Engineer & Quality Engineer ) participate in checking/confirming technical special processes, such as polarity of chips and direction of through hole connectors.

○ First article confirmation;

○ 100% AOI checking;

○ Program and function test( if necessary).

Tel: +86-13221099899

Whatsapp: 8613221099899

Email: sales@pcbnpi.com

Add:Floor 2nd,Building #1,NO.5 Fengcheng RD,Yuhang District,Hangzhou,China